To fix drag on a baitcaster, start by disassembling the reel and cleaning all components. Ensure the drag system is lubricated properly after cleaning.

Experiencing issues with a baitcaster’s drag can be frustrating for anglers of all levels. Proper maintenance and timely repairs ensure that your fishing trips don’t end in disappointment. A baitcaster’s performance heavily relies on its drag system, which allows for smooth line release when a fish takes your lure or bait.

Over time, dirt, debris, and corrosion can interfere with the drag’s functionality, causing it to stick or release unevenly. With straightforward tools and a bit of know-how, you can swiftly troubleshoot and resolve drag problems, maintaining your baitcaster in peak condition for your next angling adventure. It’s crucial to approach the task methodically to avoid further damage to your reel’s intricate components. Let’s check How to Fix Drag on Baitcaster?

Understanding Baitcaster Drag Issues

Baitcaster reels, lauded for their precision casting and control during angling pursuits, feature a critical component known as the drag system. This system is quintessential in managing the resistance a fish feels when hooked, averting the likelihood of line breaks and lost catches. Understanding and rectifying issues with baitcaster drag systems can significantly enhance an angler’s efficiency. Below is an insight into the nature of baitcaster drag issues and pragmatic solutions to ensure optimal performance on the water.

Common Problems With Baitcaster Drag Systems

Identifying and understanding common drag issues is the first step in troubleshooting a baitcaster reel. The complexity of these systems can lead to several types of malfunctions, which, if left unchecked, could impair reel performance and spoil the angling experience.

Inconsistent Drag Pressure

- Spool tension inconsistencies: These can result in erratic drag, affecting casting accuracy and line retrieval.

- Wear and tear on drag washers: Degraded components can cause irregular drag pressure, calling for periodic inspection and replacement.

Drag Sticking Or Not Engaging

The sensation of drag sticking or failing to engage is commonly attributed to mechanical issues within the reel. Overlooking these signs can result in tackle failure and potential loss of catch. Identifying the root cause typically involves disassembling the drag system for a detailed evaluation.

Excessive Noise During Drag Operation

A well-maintained drag system should operate smoothly and quietly. Excessive noise, such as grinding or clicking sounds, can indicate improper lubrication or the presence of debris. Regular cleaning and lubrication are essential to preventing noise-related issues and prolonging the lifespan of the drag system.

Identifying The Root Cause

Anglers know the thrill of a perfectly cast line, but a baitcaster that drags can turn that joy into frustration. To ensure your gear operates smoothly, it’s crucial to tackle the root cause of drag issues. Let’s take a closer look at potential culprits and how to address them.

Examining The Reel For Signs Of Wear

Regular inspection of your baitcaster is essential to maintain peak performance. Begin by scrutinizing the reel’s physical condition. Look for noticeable signs such as:

- bent frames or spools that could impede rotation,

- worn-out bearings that decrease smoothness,

- damaged gear teeth which might disrupt engagement.

Spotting telltale signs early can save you from a future tussle with underperforming equipment.

Checking For Dirt, Debris, Or Corrosion

Dirty or corroded components are a common source of drag issues. Take the time to carefully dismantle the reel, paying attention to areas often overlooked such as the:

- Drag washers,

- Brake system,

- Spool shaft.

Use a soft brush or cloth to remove the accumulation of grime or salt build-up, and assess parts for any signs of corrosion that could warrant replacement.

Verifying Proper Lubrication Of Drag Components

Lubrication is the lifeline for a smooth-operating baitcaster, especially the drag system. Ensure the correct lubricant is applied to vital areas including:

- Gear mechanisms,

- Drag washers,

- Bearing surfaces.

However, too much lubricant can also attract debris, leading to increased resistance. Apply judiciously to maintain optimal functionality.

Fixing Drag Inconsistencies

Encountering drag inconsistencies can be frustrating for anglers who rely on their baitcasters for precision and reliability. A baitcaster with erratic drag not only affects the casting performance but can also result in lost catches and reduced line life. Understanding how to diagnose and fix these drag issues is vital to get back to smooth and efficient fishing. Follow this detailed guide to address your drag inconsistencies effectively.

Adjusting The Drag Settings

Locating your reel’s drag system is the first step to solving any drag issues. Typically, it’s a star-shaped dial situated close to the handle. Turning it clockwise increases tension while turning it counterclockwise reduces tension. The goal is to set the drag to a point where it is tight enough to fight a fish but not so tight that it breaks the line. Achieving this balance is crucial:

- Start with a loose drag and tighten it gradually while pulling on the line.

- Adjust until you feel consistent resistance without any jerks or hitches.

Anglers should regularly test and adjust these settings to account for changes in fishing conditions or line wear.

Understanding The Impact Of Spool Tension

The spool tension knob, often confused with the drag system, directly influences casting performance and spool speed. However, improper spool tension can indirectly affect drag consistency:

- Locate the spool tension knob, typically at the side of the reel.

- Adjust the knob so the lure falls slowly and smoothly when you release the baitcaster’s thumb bar or spool release.

- Ensure that the lure does not cause the spool to overrun when it hits the water; this minimizes backlashes and provides a more consistent drag performance.

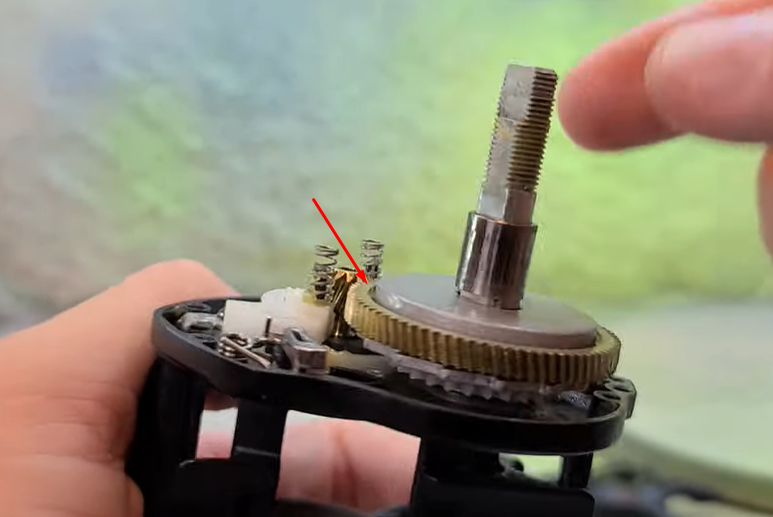

Properly Aligning Drag Washers

Inconsistent drag can often be a result of misaligned drag washers. These washers are critical for providing smooth resistance and must be properly seated. Here’s how to check and align them:

- Disassemble the drag system carefully, according to your baitcaster’s manual.

- Inspect the drag washers for wear or damage. Replace them if necessary.

- When reassembling, ensure the washers are clean and placed correctly in their designated spots.

Using the correct lubricant for the washers can also enhance drag performance. Be sure the lubricant is designed for fishing reels to prevent any potential damage or further inconsistencies.

Maintenance And Prevention

Fishing enthusiasts know that a smooth-operating baitcaster can mean the difference between a good day of fishing and a frustrating one. Consistently experiencing drag issues can be a sign that your reel requires some attention. Maintenance and prevention are key to keeping your baitcaster in top condition, ensuring that drag problems don’t cut your trip short or cost you your catch. Effective maintenance involves regular cleaning, proper lubrication, and a commitment to upkeep. Let’s look into how this can be achieved.

Cleaning And Lubricating The Drag System

Regular cleaning is crucial to prevent debris and dirt from causing drag issues in your baitcaster. Accumulated grime can impede the reel’s performance and increase wear on the components. The process should be gentle, using tools that are designed not to damage the delicate parts of the drag system.

- Disassemble the drag system carefully according to the manufacturer’s instructions.

- Wipe down each part with a soft cloth to remove loose dirt.

- Use a cotton swab or soft brush for hard-to-reach areas.

Proper lubrication follows cleaning, ensuring that every reassembled component moves smoothly without resistance or noise. The type of lubricant used will have a significant effect on performance and longevity.

- Apply a high-quality reel oil or grease designed for baitcasters.

- Target the bearings, spool shaft, and drag washers, applying sparingly.

- Reassemble the parts to complete the process.

Using Appropriate Cleaning Solutions And Lubricants

Selecting the right cleaning solutions and lubricants can make a world of difference. Use only cleaners and lubricants made specifically for fishing reels to avoid corrosion and buildup. Abrasive or heavy-duty cleaners can damage the components, while the wrong lubricants may gum up the mechanism or attract more dirt.

Establishing A Regular Maintenance Routine

Forming a regular maintenance routine is vital for preventing drag issues. With consistent care, your baitcaster will operate smoothly, providing reliability when you need it most. Scheduling sessions based on usage frequency keeps performance optimal.

| After Every Use | Monthly | Seasonally |

|---|---|---|

| Wipe down the reel | Clean and lubricate drag system | Inspect for wear and tear |

| Check for line damage | Check brake system | Deep clean entire reel |

Testing And Fine-tuning

Ensuring that your baitcaster’s drag is set to perfection is not just about making initial adjustments; it’s about meticulous testing and fine-tuning for the smoothest experience. Drag system performance is crucial for battling the catch without line breakage or reel damage. Follow these strategic steps to test and adjust your baitcaster’s drag, ensuring your next fishing trip is an unprecedented success.

Conducting Drag Tests Before And After Adjustments

Begin by conducting a baseline test to evaluate the current drag setting. A simple yet effective way to do this is to use a spring scale or a luggage scale. Attach the scale to the line just above your reel and pull steadily. Note the weight at which the line begins to release from the reel. This measurement serves as a reference for your initial drag strength. After making any adjustments, repeat the test. The drag should engage at about one-third of the line’s breaking strength for an optimal setting.

Evaluating Smoothness And Consistency Of Drag Operation

A well-performing drag system should operate smoothly without jerky or intermittent movements. Perform a qualitative assessment by tugging on the line at different angles and speeds. Feel for any irregularities or abrupt changes in resistance. Smooth drag operation indicates a well-maintained reel and ensures that the line is less likely to snap under sudden pressure from a hooked fish.

Making Final Adjustments For Optimal Performance

- Step 1: Start with small increments. Adjust your baitcaster’s drag knob in slight turns to avoid over-loosening or tightening.

- Step 2: Test drag pressure after each adjustment. Use your spring scale to measure the pressure, aiming for consistent readings.

- Step 3: Be meticulous. Record your results and keep testing until you reach that perfect balance between too much and too little tension.

- Step 4: Once the desired setting is achieved, lock your drag into place to avoid any unintended adjustments during your fishing session.

With the drag precisely set, your baitcaster should now perform efficiently under strain, playing the fish without causing undue stress to your line. Remember, even the best settings may need finetuning as conditions change, so stay observant and adjust as necessary.

Frequently Asked Questions For How To Fix Drag On Baitcaster

Why Does My Baitcaster Have Drag Issues?

A baitcaster may develop drag issues due to improper maintenance, wear, and tear, or incorrect settings. Regular cleaning and correct adjustment of the drag system can prevent these problems.

How Do I Adjust My Baitcaster’s Drag Properly?

To adjust your baitcaster’s drag, turn the drag knob clockwise to tighten or counterclockwise to loosen. Always set the drag according to the line strength and the fish you’re targeting.

What Causes Baitcaster Reel Resistance?

Baitcaster reel resistance, or drag, can be caused by dirt or debris in the drag system. Over-lubrication or a worn-out drag washer can also increase resistance, affecting performance.

Can I Repair The Drag On My Baitcaster Myself?

Yes, you can repair the drag on your baitcaster by disassembling the reel, cleaning all parts thoroughly, replacing any worn components, and reassembling according to the manufacturer’s instructions.

Conclusion

Mastering baitcaster drag adjustment brings you closer to a seamless fishing experience. Follow these steps to ensure a smooth cast every time. Embrace the finesse of your tackle adjustments – your catch rate might just soar. For further fishing insights, keep exploring our blog.

Tight lines and happy casting!